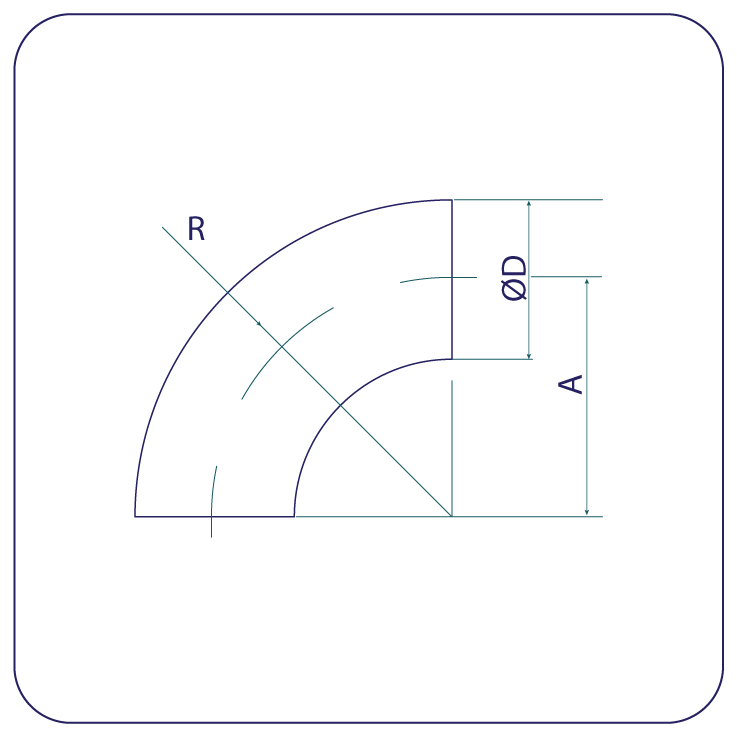

DIN 11852 90 Degree Stainless Steel Bends – Reliable Connections, Premium Quality

These DIN 11852 90° Bends, deliver exceptional performance and durability in demanding piping applications. Built to the highest German standards, these bends guarantee precision, reliability, and resistance to corrosion – vital factors for longevity and operational safety.

Constructed from premium 316L stainless steel, these 90-degree bends meet the stringent requirements of DIN 11852, ensuring dimensional accuracy and consistent material composition. This grade of stainless steel is renowned for its superior resistance to pitting, crevice corrosion, and stress corrosion cracking, even in harsh chemical environments.

- Material: 316L Stainless Steel – Providing exceptional corrosion resistance.

- Standards: DIN 11852 – Guaranteeing adherence to international quality benchmarks.

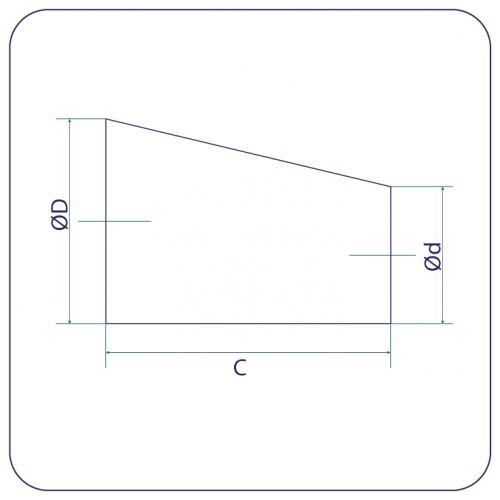

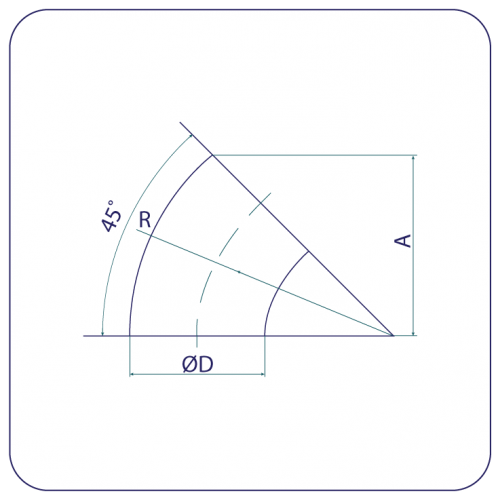

- Dimensions: (See sizing table) – Precise dimensions for seamless integration.

- Weldability: Readily weldable using standard stainless steel welding techniques.

- Applications: Ideal for chemical processing, pharmaceutical manufacturing, food & beverage, wastewater treatment, and marine applications.

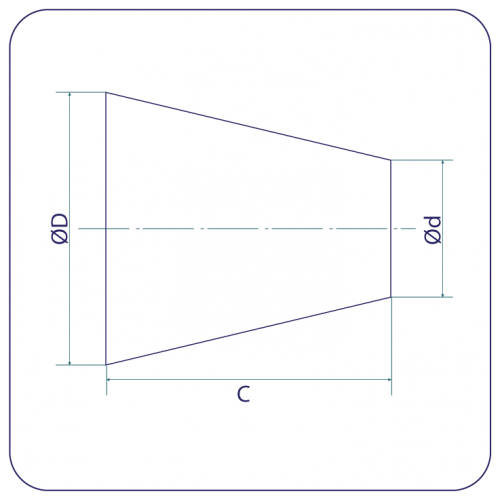

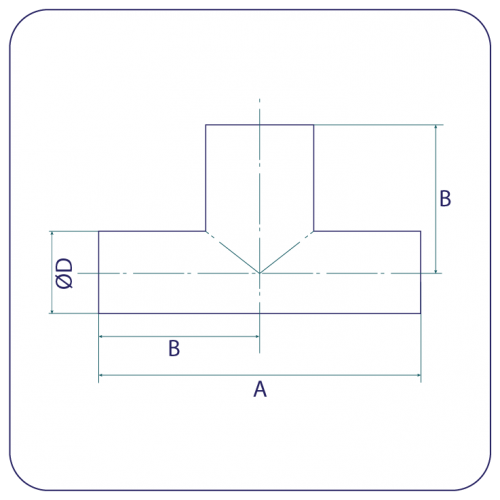

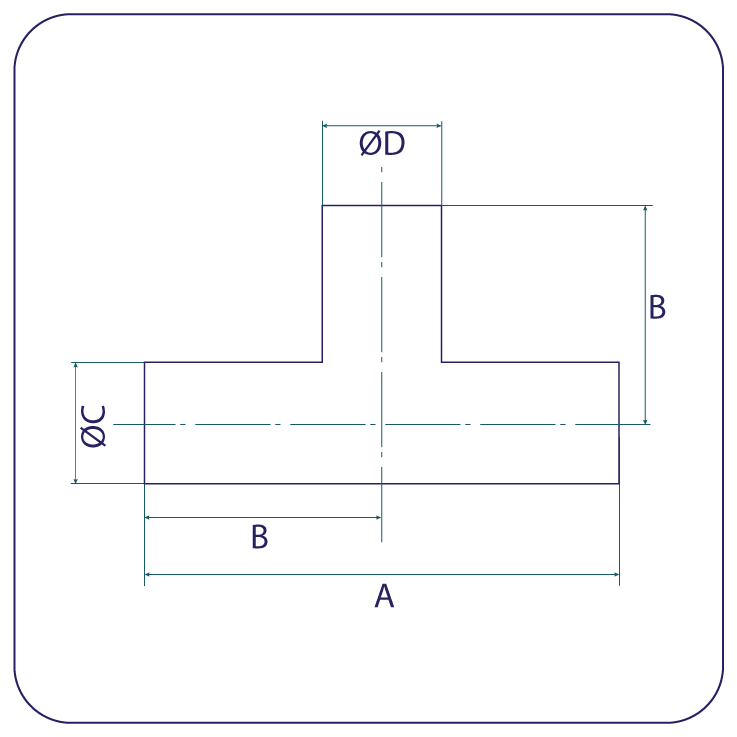

These DIN 11852 Grade 316L reducing tees are ideal for:

Benefits

- Enhanced Corrosion Resistance: Minimizes the risk of component failure and extends system lifespan.

- Precise Dimensional Accuracy: Ensures seamless integration into existing piping systems.

- High Weldability: Facilitates easy and reliable connections.

- Compliance with DIN 11852: Guaranteed quality and performance.

Furthermore, the design ensures robust connections, minimizing leakage risks and maximizing system efficiency. These 90-degree bends are a dependable investment for any project requiring a high-quality, corrosion-resistant piping solution. The smooth internal surface also reduces flow restrictions, improving overall system performance.

Choose our DIN 11852 90° Bends for peace of mind and long-lasting performance. Contact us today for a competitive quote and tailored solutions.

| Tube Size | A | Tube OD (mm) | R | DN 10 | 26 | 13 | 26 |

|---|---|---|---|

| DN 15 | 35 | 19 | 35 |

| DN 20 | 40 | 23 | 40 |

| DN 25 | 50 | 29 | 50 |

| DN 32 | 55 | 35 | 55 |

| DN 40 | 60 | 41 | 60 |

| DN 50 | 70 | 53 | 70 |

| DN 65 | 80 | 70 | 80 |

| DN 80 | 90 | 85 | 90 |

| DN 100 | 100 | 104 | 100 |